energy optimisation

Energy-efficient production with economic benefits

Sintering processes are among the most heat-intensive in the metal industry. In stages such as pre-compaction, high-temperature sintering, and subsequent heat treatment, large volumes of waste heat are released – often as flue gas or process air at high temperatures.

With Exodraft’s heat recovery solutions, this energy can be captured and reused – for example, for heating production halls, domestic water or process water. This creates a more energy-efficient production setup and delivers financial benefits for companies manufacturing gears, bushings, filters, or other precision components using powder metallurgy techniques.

The solution is engineered to operate in extreme temperature environments with continuous production – without interfering with the precise control required in sintering.

Sinter metal industry

Why heat recovery is relevant for the sinter metal industry

In sintering, metal components gain their desired properties through extremely high temperatures in long-duration furnace cycles. These furnaces are among the largest sources of heat emissions in production. Without heat recovery, this energy is lost – even though heating is often needed elsewhere within the facility.

Additionally, supporting processes such as preheating, degassing, and post-hardening are highly energy-demanding and often run concurrently. By capturing and reusing waste heat from furnaces and process air, companies in the sinter metal industry can significantly reduce their total energy consumption – without compromising product quality or precision.

This makes heat recovery an efficient and strategic solution in a sector where thermal control and energy efficiency go hand in hand.

Take the test

Get energised by contributing to a more sustainable future

Let us help you! – We custom solutions for recovering your waste heat, so you can optimize your energy efficiency for the benefit of both the environment and your business.

Can I recover my wast heat?

You can recover up to 95% of waste heat from process air, steam, and flue gases. The surplus energy can be stored or used directly to optimize production processes.

Why heat recovery is important

There are increasing demands for us to take responsibility in the green transition. With the right system, you can reduce your carbon footprint and costs.

Will the investment benefit my business

Our solutions not only enhance your green profile but also improve your financial bottom line. Typically, the investment pays off in 2-3 years.

a great investment

How sinter metal companies utilise waste heat

I produktion af sintermetalkomponenter opstår der n sintered component production, heat is emitted at multiple stages – during heating, sintering, cooling and post-treatment. With Exodraft’s systems, this heat can be captured directly from furnaces, extraction systems and heat exchangers – and redirected to other uses within the facility.

Typical applications include:

- Heating of production halls and office spaces

- Domestic hot water for cleaning and staff facilities

- Preheating of process water for degassing or surface treatment

- Absorption cooling – using surplus heat for cooling during warm periods

- Export to district heating networks, where applicable

- Strengthened ESG profile and CO₂ documentation

This type of reuse not only generates energy savings – it also provides greater control over internal heat balance and improves operational flexibility.

metal component production

Benefits of Exodraft’s solutions for metal component production

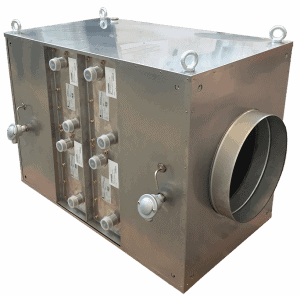

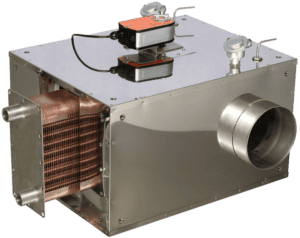

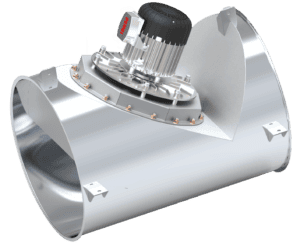

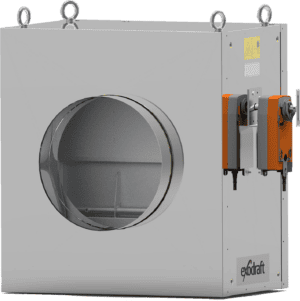

Exodrafts systemer er robuste, højtemperaturtolerante og sExodraft’s systems are robust, high-temperature-tolerant, and tailored for demanding environments like sinter metal and metal component manufacturing.

Benefits for your business:

- Efficient reuse of heat from sintering and heat treatment

- Lower energy consumption and reduced operational costs

- Integration into both new and existing production lines

- Documented CO₂ reduction and strengthened ESG reporting

- High performance and long system lifespan

Whether you produce gears, bearings, filters or other components, heat recovery gives you a measurable advantage – both technically and economically.

let us help you

Want to know how much you can save?

Heat recovery is an ideal solution for companies in the sinter metal industry looking to reduce energy use and strategically reuse waste heat. At Exodraft, we help you identify the potential in your production and tailor a solution to your specific needs.

Try our Energy Calculator or contact us today for a no-obligation assessment of your savings potential and how to make your operations more sustainable.

exodraft