energy optimisation

We have the solution that meets your requirements

Metal processing – especially melting and forming – ranks among the most heat-intensive processes in the industrial sector. The high operating temperatures generate vast amounts of surplus heat, which is often lost through extraction or cooling systems.

With heat recovery from Exodraft, this energy can be reused and reintegrated into the cycle – where it creates value. Whether for heating buildings, preheating process water, or supplying hot water for cleaning, waste heat can be utilised effectively.

Our solutions are engineered to meet the technical requirements and demanding operating conditions typical of metalworking – and can be implemented without disrupting production.

metal processing

Why heat recovery is relevant for metal processing

Processes such as melting, rolling, welding, and milling produce significant amounts of heat – far more than what is consumed directly in production. Without heat recovery, this energy disappears into the air, while the company continues to pay for fresh energy to meet heating and operational needs.

At the same time, demands for energy savings and sustainability are intensifying. Customers, authorities, and internal ESG targets all call for reduced CO₂ emissions and more efficient resource management. Heat recovery offers a direct and measurable solution: lower energy consumption, reused surplus heat – benefiting both the economy and the environment.

That makes heat recovery an obvious step for metalworking businesses aiming to optimise operations and future-proof their production.

Take the test

Get energised by contributing to a more sustainable future

Let us help you! – We custom solutions for recovering your waste heat, so you can optimize your energy efficiency for the benefit of both the environment and your business.

Can I recover my waste heat?

You can recover up to 95% of waste heat from process air, steam, and flue gases. The surplus energy can be stored or used directly to optimize production processes.

Why heat recovery is important

There are increasing demands for us to take responsibility in the green transition. With the right system, you can reduce your carbon footprint and costs.

Will the investment benefit my business

Our solutions not only enhance your green profile but also improve your financial bottom line. Typically, the investment pays off in 2-3 years.

a great investment

How metalworking companies utilise waste heat

IIn metalworking, waste heat occurs at nearly every stage of the process – from furnaces to melting pots. With Exodraft’s heat recovery solutions, this heat can be effectively captured and reused.

Typical applications include:

- Heating production buildings and workshops, where heat loss is often high

- Heating domestic water for staff facilities or cleaning

- Preheating process water for direct use in manufacturing operations

- Absorption cooling – enabling heat to be repurposed for cooling applications

- Export to district heating networks, where technically and legally feasible

- Strengthening ESG profile and CO₂ documentation

With a heat recovery system in place, surplus energy is reintegrated into production – reducing overall consumption and improving operational economics.

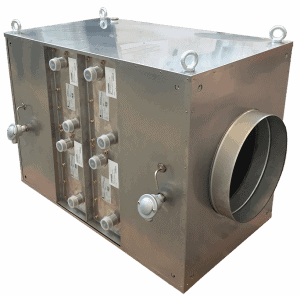

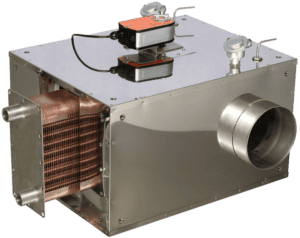

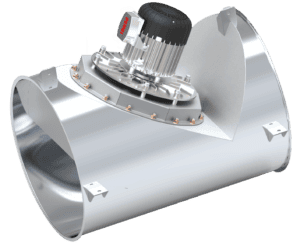

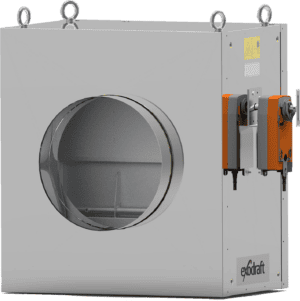

solutions for metal processing

Benefits of Exodraft’s solutions for metal processing

Exodraft’s solutions are built for industrial environments where high temperatures, dust, and tough operating conditions are the norm – just like in metalworking. Our systems are modular, energy-efficient, and customisable for both new and existing installations.

Benefits for your business:

- Reduced energy consumption and thermal emissions

- Documented savings and short payback time

- Improved utilisation of existing energy resources

- Scalable systems for both small and large production environments

- Enhanced sustainability profile and reduced CO₂ footprint

With Exodraft, you gain a solution that delivers visible results – supporting both technical performance and strategic objectives.

let us help you

Want to know how much you can save?

Heat recovery is a clear opportunity for metalworking companies looking to reduce energy consumption and strategically reuse surplus heat. At Exodraft, we help you identify the potential within your production – whether you specialise in melting, forming, or further processing.

Try our Energy Calculator or contact us today for a no-obligation assessment of how much you could save – both in energy costs and climate impact.

exodraft