energy optimisation

Recover surplus heat and reintegrate it into your production

The production of metal packaging – particularly where printing, coating and curing are involved – is associated with high heat generation and substantial energy demand. Drying lines, ovens and printing presses emit significant amounts of heat, which is often discharged as waste.

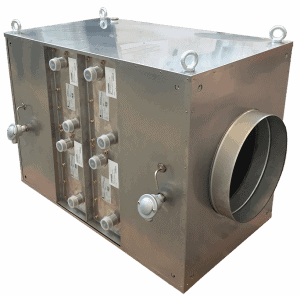

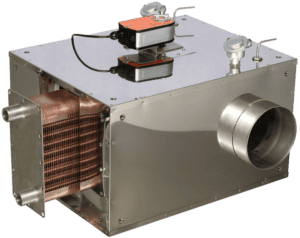

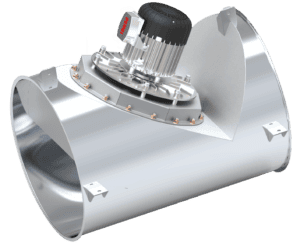

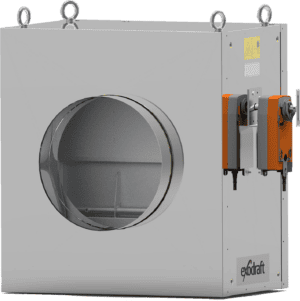

With heat recovery from Exodraft, surplus heat can be captured and reintegrated directly into the production process – benefiting both energy consumption and operational costs. Whether you work with cans, lids, aerosols, tubes or metal caps, our solution can be integrated seamlessly into your production – without compromising quality or performance.

metal printing and packaging

Why heat recovery is relevant for metal printing and packaging

Industries such as beverage packaging, cosmetic and pharmaceutical containers, as well as paint and chemical tins, rely heavily on printing and drying systems in their production. These processes often run around the clock and generate substantial waste heat – especially from curing ovens and exhaust systems.

Heat recovery is an effective way to reuse this energy, reduce thermal emissions, and decrease reliance on external energy sources. It’s a solution that makes sense economically – while also supporting the industry’s growing focus on sustainability and responsible manufacturing.

Take the test

Get energised by contributing to a more sustainable future

Let us help you! – We custom solutions for recovering your waste heat, so you can optimize your energy efficiency for the benefit of both the environment and your business.

Can I recover my waste heat?

You can recover up to 95% of waste heat from process air, steam, and flue gases. The surplus energy can be stored or used directly to optimize production processes.

Why heat recovery is important

There are increasing demands for us to take responsibility in the green transition. With the right system, you can reduce your carbon footprint and costs.

Will the investment benefit my business

Our solutions not only enhance your green profile but also improve your financial bottom line. Typically, the investment pays off in 2-3 years.

a great investment

How metal printers utilise waste heat

Waste heat can be captured directly from drying lines, exhaust systems and technical equipment – and reused wherever there’s demand in the production flow.

Typical applications include:

- Preheating process water, e.g. for pre-treatment or component washing

- Heating of production halls and office areas

- Domestic water for cleaning and sanitation

- Absorption cooling – enabling heat to be repurposed for cooling during warm periods

- Export to district heating networks, where feasible

- Strengthening ESG profile and CO₂ documentation

Each solution is tailored to the specific production process and implemented with minimal disruption to the existing setup.

metal printing and packaging production

Benefits of Exodraft’s solutions for metal printing and packaging production

Exodraft’s systems are robust and scalable – ideal for complex production environments involving printing and curing. We offer solutions for both large packaging factories and specialised printing facilities, and our systems can be easily adapted to different production lines.

Key benefits include:

- Reduced energy consumption and thermal emissions

- Optimised utilisation of heat from drying and curing processes

- Enhanced sustainability profile and ESG documentation

- Flexible integration into existing production environments

- Short payback period and low maintenance requirements

let us help you

Want to know how much you can save?

Heat recovery is a clear opportunity for packaging and metal printing facilities seeking to get more from their existing energy. We help you evaluate the potential and tailor a solution specifically for your production needs.

Try our Energy Calculator or contact us today for a no-obligation assessment of your energy savings and heat recovery potential.

exodraft