energy optimization

Lower energy consumption – more sustainable operation

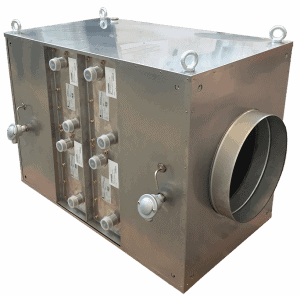

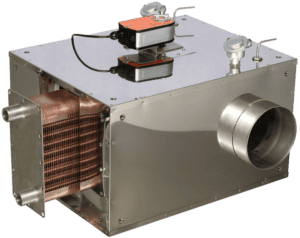

With Exodraft’s heat recovery solutions, excess heat from sources such as gas boilers or exhaust air can be captured and reused for other purposes within the production process. This means lower energy consumption, reduced waste, and more sustainable operations – without compromising hygiene standards or process stability.

Whether you’re blanching vegetables or working in other areas of food processing, we can deliver a solution tailored to your process and production setup.

food processing

Why heat recovery is relevant for food processing

Food processing requires significant energy for heating, cleaning and process control – often in round-the-clock operations and temperature-sensitive environments. Whether it’s blanching, pasteurising, or cleaning production equipment, large volumes of waste heat are generated and often lost.

At the same time, food production must meet stringent demands for both hygiene and energy optimisation – making heat recovery particularly relevant. By reusing excess heat, companies can significantly reduce their energy consumption while meeting sustainability and financial responsibility goals.

Heat recovery is not just a technical upgrade – it’s a strategic investment in production optimisation and green transition.

Take the test

Get energised by contributing to a more sustainable future

Let us help you! – We custom solutions for recovering your waste heat, so you can optimize your energy efficiency for the benefit of both the environment and your business.

Can I recovery my waste heat?

You can recover up to 95% of waste heat from process air, steam, and flue gases. The surplus energy can be stored or used directly to optimize production processes.

Why heat recovery is important

There are increasing demands for us to take responsibility in the green transition. With the right system, you can reduce your carbon footprint and costs.

Will the investment benefit my business

Our solutions not only enhance your green profile but also improve your financial bottom line. Typically, the investment pays off in 2-3 years.

a great investment

How food companies utilise waste heat

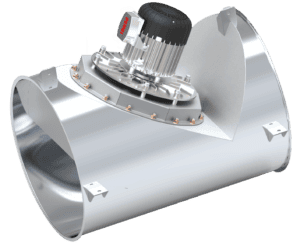

The food industry produces a constant flow of heat – especially from processes such as steaming, blanching, and boiling. Exodraft’s heat recovery solutions make it possible to capture this energy and apply it where it provides the greatest value.

Typical applications include:

- Heating domestic hot water, e.g. for cleaning and CIP (Clean-in-Place) systems

- Heating buildings and staff facilities

- Cleaning operations where hot water is a hygienic necessity

- Absorption cooling to manage heat challenges during summer periods

- Export to district heating networks, turning excess heat into a new source of revenue

- Strengthening ESG profile and CO₂ documentation

By integrating heat recovery into your food production, you not only achieve savings but gain greater control over your energy flows and reduce dependency on external energy sources.

food industry

Benefits of Exodraft’s solutions for the food industry

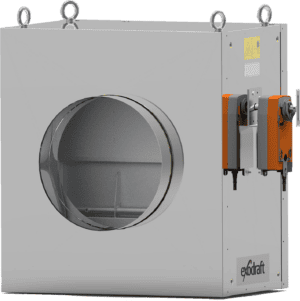

Exodraft offers heat recovery systems customised to the high demands of food processing – both in regard to hygiene, operational reliability, and energy efficiency. Our solutions are flexible and can be installed in existing facilities or integrated into new production lines.

Key benefits for your food processing business:

- Measurable energy savings and reduced operational costs

- Enhanced environmental profile and improved CSR and ESG reporting

- Adaptation to process requirements and production flow

- Integration with CIP and hot water systems

- Increased supply security and flexibility in energy use

We ensure that heat recovery becomes a value-adding part of your production – with a focus on both performance and long-term operation.

exodraft

Want to know how much you can save?

Exodraft’s heat recovery solutions help food companies capture waste heat from production and turn it into measurable savings. We analyse your processes, identify the potential, and deliver a solution that fits your needs – all without disrupting operations.

Try our Energy Calculator or contact us today for a no-obligation assessment of how heat recovery can improve both your bottom line and sustainability in food production.

exodraft