energy optimization

Reduce energy consumption and optimise your operating costs

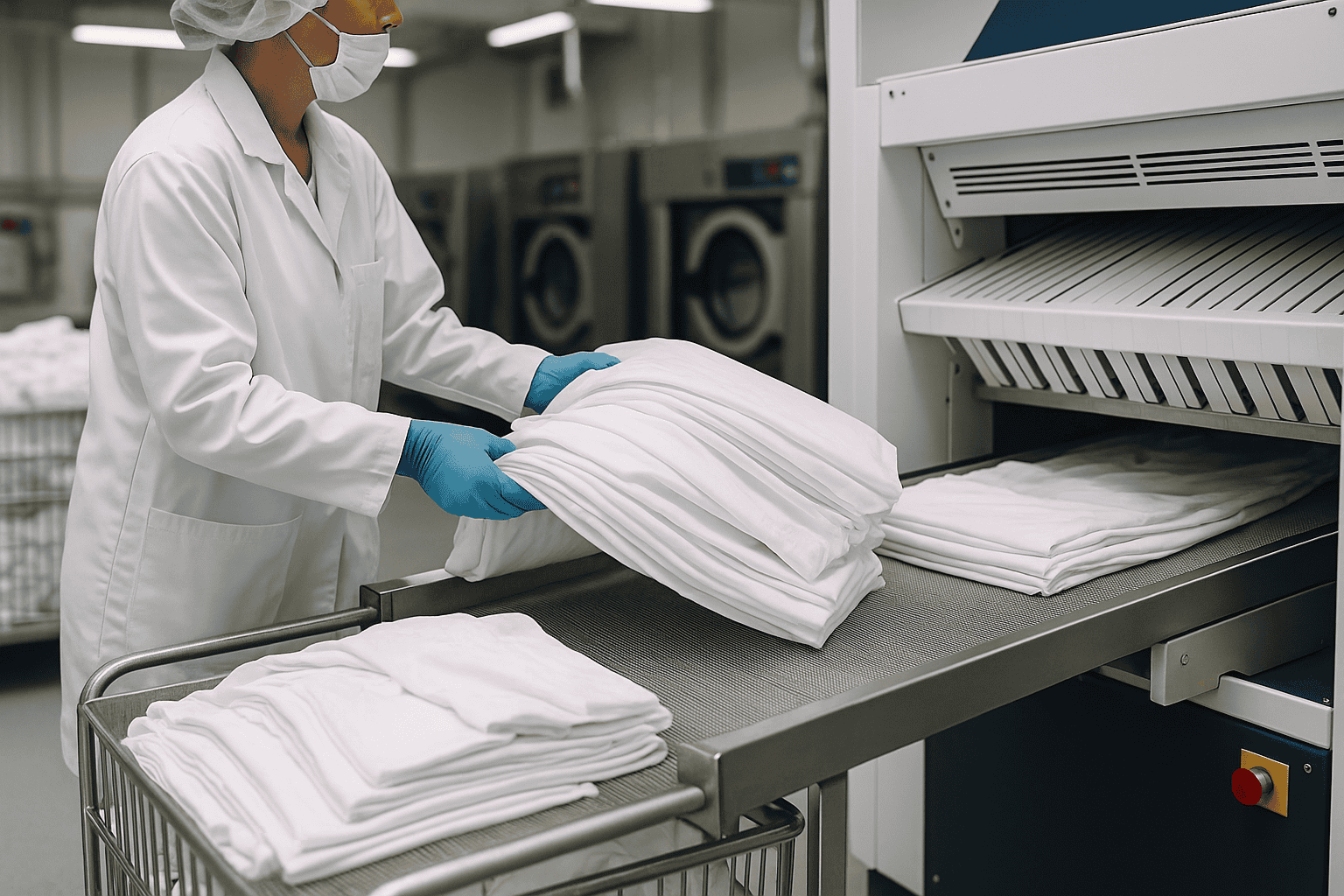

Commercial laundries handle large volumes of textiles at high temperatures – often operating around the clock. Hot water, steam and warm air are essential in washing, rinsing and drying processes, resulting in significant waste heat.

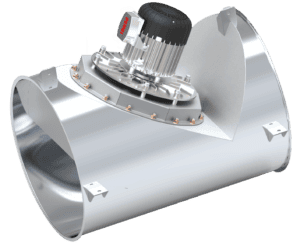

With Exodraft’s heat recovery systems, energy from exhaust air, tumble dryers, and hot water systems can be captured and reused – for example, to heat fresh water supplies, indoor spaces, or for cleaning purposes. This dramatically reduces both energy consumption and thermal emissions.

Our solutions can be implemented in everything from industrial laundries to centralised laundry facilities for hotels, hospitals and the food industry – and are customised to meet your specific operational needs.

laundry sector

Why heat recovery is relevant for the laundry sector

Commercial laundries consume vast amounts of hot water and energy to ensure high hygiene standards, fast turnaround, and efficient drying. Heat is primarily lost through industrial washing machines, tumble dryers, and extraction systems – which represents a major loss if not recovered.

At the same time, there’s a continuous need for heated water for washing cycles, as well as for cleaning and climate control within the facilities. By capturing and reusing waste heat internally, laundries can significantly reduce their energy demand – without compromising wash quality or operational speed.

Heat recovery presents an ideal opportunity to combine cost savings with sustainable operation in a sector where resource use is under increasing scrutiny.

Take the test

Get energised by contributing to a more sustainable future

Let us help you! – We custom solutions for recovering your waste heat, so you can optimize your energy efficiency for the benefit of both the environment and your business.

Can I recovery my waste heat?

You can recover up to 95% of waste heat from process air, steam, and flue gases. The surplus energy can be stored or used directly to optimize production processes.

Why heat recovery is important

There are increasing demands for us to take responsibility in the green transition. With the right system, you can reduce your carbon footprint and costs.

Will the investment benefit my business

Our solutions not only enhance your green profile but also improve your financial bottom line. Typically, the investment pays off in 2-3 years.

commercial laundries

How commercial laundries utilise waste heat

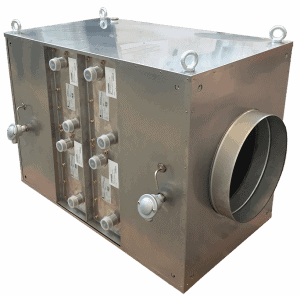

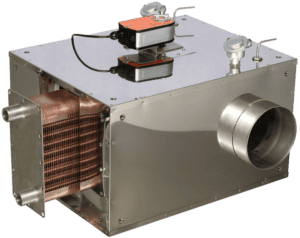

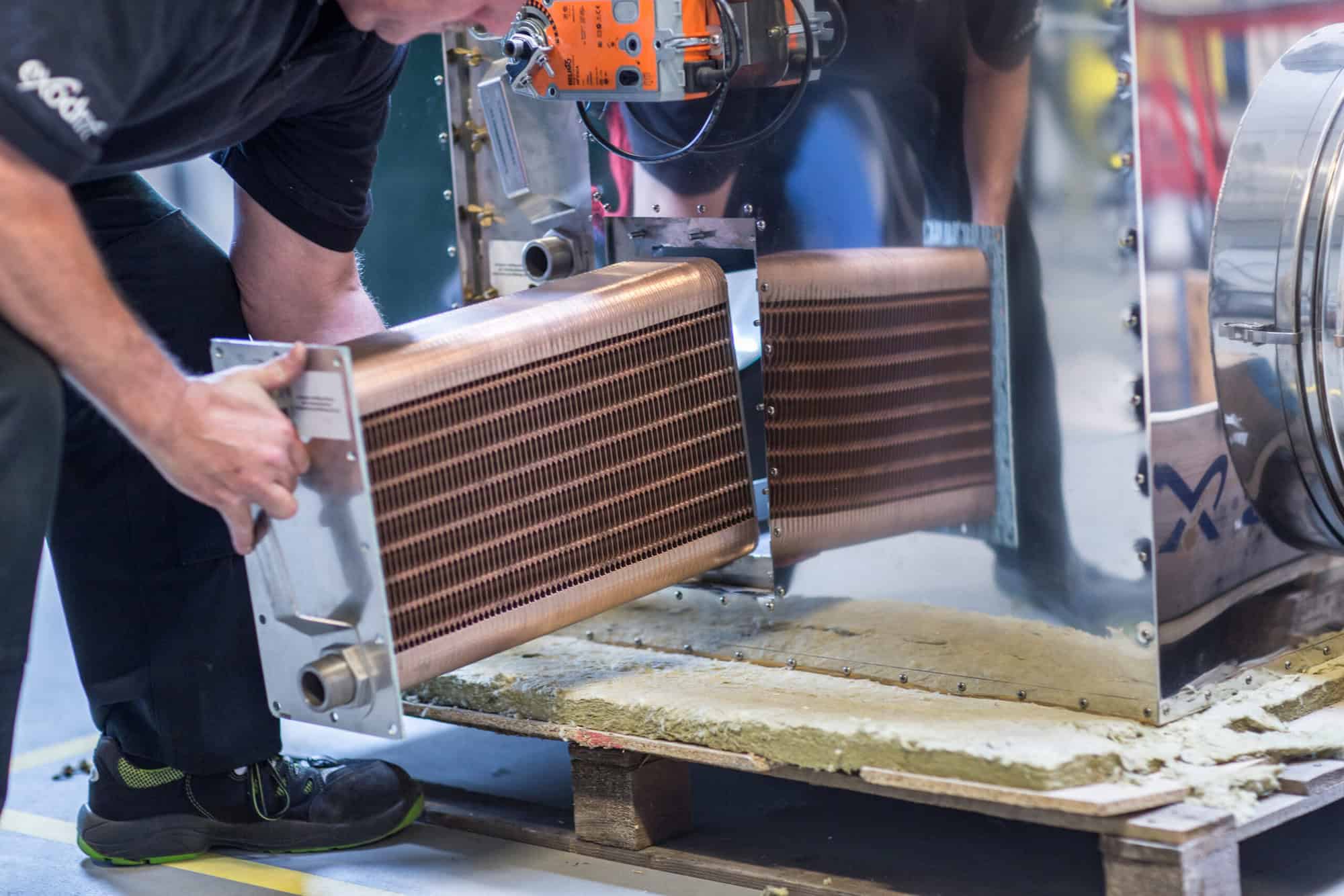

In commercial laundries, waste heat is especially released from tumble dryers, heat exchangers, and exhaust air, where the temperature is often high and stable. With Exodraft’s systems, this heat can be collected and directed to new energy applications within daily operations.

Examples of application:

- Preheating process water for the next wash cycle

- Heating cleaning water for machines and facility hygiene

- Space heating in production halls and technical rooms

- Strengthening ESG profile and CO₂ documentation

By recirculating heat back into production, you achieve energy savings and more balanced temperature control – without affecting hygiene standards or capacity.

benefits for laundries

Benefits of Exodraft’s solutions for laundries

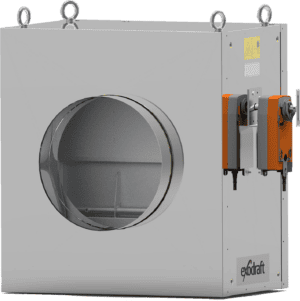

Exodraft’s heat recovery systems are designed to operate in environments with high humidity, steam, and continuous usage – exactly the conditions found in commercial laundries. Our solutions are compact, energy-efficient and easy to integrate into existing installations.

Benefits for your laundry operation:

- Reuse of heat from extraction and drying processes

- Reduced energy costs and heat emissions

- High operational reliability and low maintenance

- Tailored solutions for laundries of all sizes

- Improved sustainability profile and documented CO₂ reduction

We deliver solutions that support both economic performance and environmental responsibility – without compromising on operational efficiency.

Let us help you

Want to know how much you can save?

Heat recovery is an effective solution for commercial laundries looking to reduce their energy use and optimise performance. At Exodraft, we help you identify where waste heat arises in your laundry production – and how it can best be utilised.

We tailor the solution to your processes and building infrastructure, whether you run a stand-alone industrial laundry or a laundry centre linked to the hotel, healthcare, or food sectors.

Try our Energy Calculator or contact us today for a no-obligation assessment of how much you could save – both financially and environmentally.

exodraft