“The collaboration was consistently shaped by a solution-oriented approach.

– Hr. Schmöller, Energy Manager – Herbert Bauer GmbH & Co

Challenges were identified early and addressed constructively with a clear focus on results.

What stood out in particular was the open and respectful communication on equal terms, which created a strong and trusting working atmosphere.

Honesty and mutual trust formed the foundation of our cooperation and enabled transparent decisions throughout the process.

The availability and rapid response times contributed significantly to keeping everything running smoothly.

Overall, we experienced a high level of professionalism, commitment, and reliability – qualities that are extremely important to us as a customer.”

Project description

Valuable heat energy directly for production

When Herbert Bauer GmbH & Co – a respected name in surface treatment and mechanical processing – set out to integrate heat recovery into their running production lines, they needed more than just components. They required a complete, efficient solution that could be implemented without disrupting their operations.

We delivered a tailored, turnkey heat recovery setup comprising two independent systems – one for their thermal afterburning unit and one for a high-performance drying oven. From initial concept to final commissioning, every stage was managed in-house, ensuring full accountability and technical precision.

The implemented systems now return valuable thermal energy directly back into the production cycle, reducing energy costs while supporting the company’s drive towards more sustainable manufacturing. With our support, Herbert Bauer GmbH & Co gained not only operational savings but also a long-term energy strategy that fits seamlessly into their existing infrastructure.

The customer

Sustainability and process optimisation are firmly embedded in the company’s mindset

Herbert Bauer GmbH & Co is part of the KFB Group and has been a trusted specialist in surface finishing, steel construction, and mechanical processing for decades. From their site in southern Germany, the company delivers high-quality coating solutions including galvanising, lacquering, and powder coating, alongside precise mechanical manufacturing services.

What sets Herbert Bauer GmbH & Co apart is their dedication to protecting and perfecting metal surfaces – always with an eye on innovation and technical excellence. Their facilities are designed for high throughput and efficiency, enabling them to serve a wide range of industrial sectors. Sustainability and process optimisation are firmly anchored in their corporate mindset, making them a natural partner for advanced energy recovery solutions.

Solution specifications

Two separate heat recovery systems

To meet the needs of an active production environment with high-temperature exhaust, we installed two separate heat recovery systems tailored to different processes at Herbert Bauer GmbH & Co.

System 1 – Termisk Afterburner Line:

Det første system blev integreret i det eksisterende anlæg til termisk efterforbrænding. Selvom der tidligere var installeret The first system was integrated into the existing thermal post-combustion setup. Although a previous heat recovery unit was already installed, it lacked efficiency and left significant energy potential unused. The system was still emitting exhaust gases at approximately 280°C with a volume of 7,000 m³/h.

To capture and reuse this untapped energy, we installed:

This setup ensures optimal extraction and utilisation of thermal energy that would otherwise be wasted, redirecting it efficiently back into the production process.

System 2 – Dacral Drying Oven:

The second system targeted the drying oven line, which consists of:

- 3 burners, each producing flue gas at 300°C with an output of 1,200 m³/h, operating in a 50/50 intermittent cycle based on product load.

- 2 constant exhaust stacks, each emitting 1,400 m³/h at 300°C.

- 2 x DM350 dampers

- 1 x BP500 recovery unit

- 1 x CFIR300 fan

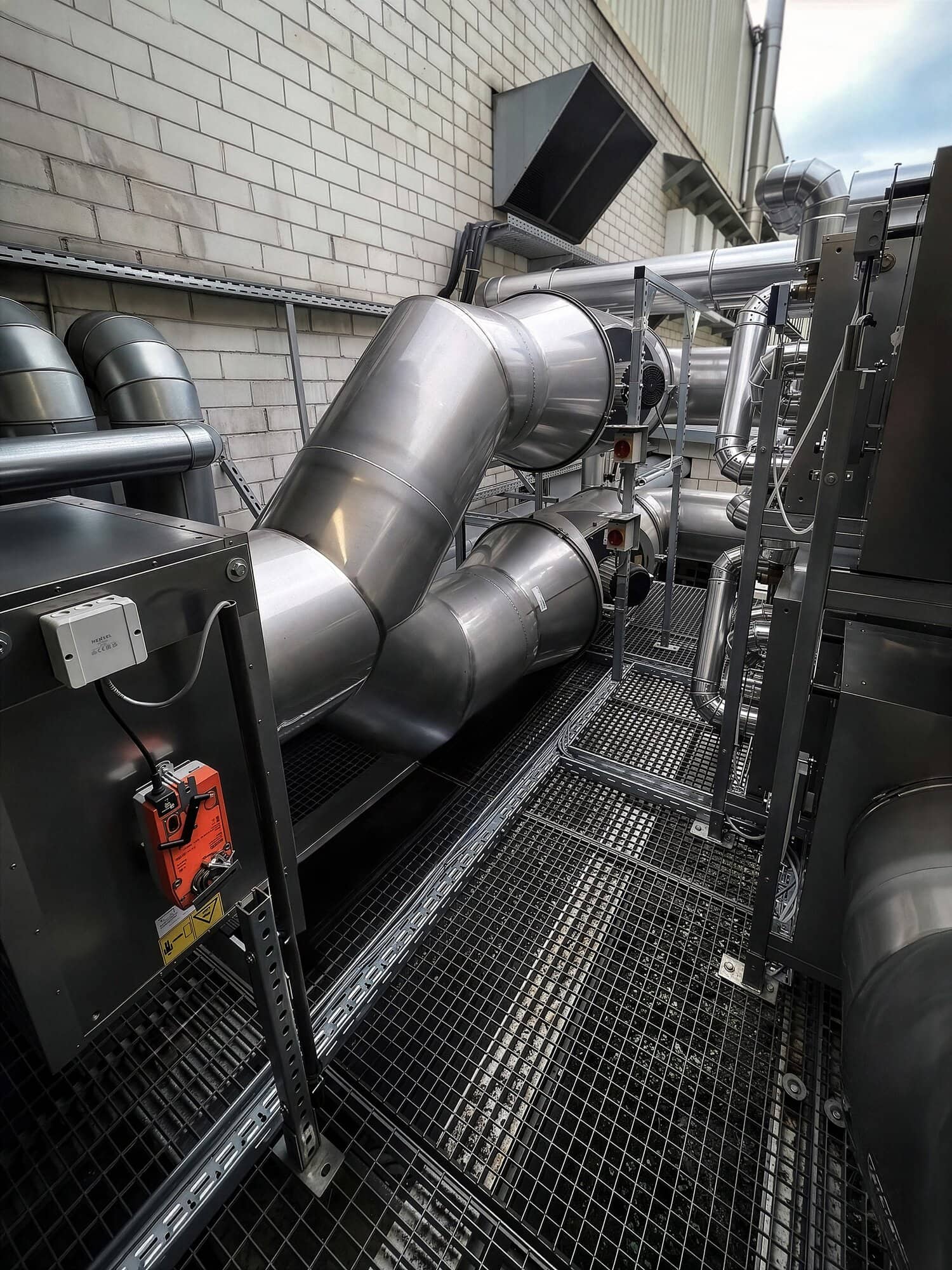

Both systems are controlled via a shared PLC unit, allowing smart, centralised management of the full heat recovery process. The fans are mounted on the building’s roof, ensuring smooth airflow and minimal acoustic impact inside the facility. This dual-system approach allows Herbert Bauer GmbH & Co to recover high-grade heat from multiple sources with varying operational patterns – all managed via a unified control interface.

Handover and results

Smooth installation and rapid commissioning ensured energy savings from day one

The installation and commissioning of both heat recovery systems were carried out with minimal disruption to production. Thanks to close coordination and transparent project planning, the integration into the existing infrastructure ran smoothly – a crucial requirement for Herbert Bauer GmbH & Co, where uptime is essential.

We ensured full functionality through a structured handover process that included on-site testing, fine-tuning, and training of key personnel. The systems were adjusted for optimal performance based on real operating conditions, ensuring immediate energy savings from day one. The result is a sustainable, cost-efficient solution that significantly reduces energy consumption while maintaining process reliability. By redirecting previously wasted heat back into the production cycle, Herbert Bauer GmbH & Co has taken a decisive step toward greener manufacturing – without compromising performance.

exodraft