we have the solution

We are here to offer you professional guidance

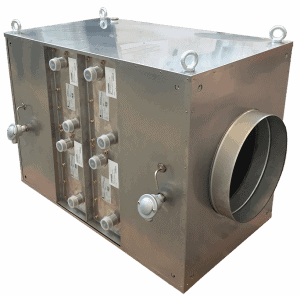

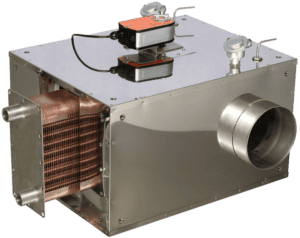

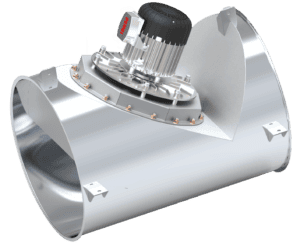

With Exodraft’s heat recovery systems, this energy can be captured and reused – for example, to heat process water, cleaning systems, or as an energy source for absorption cooling. This enables more efficient and sustainable operations without compromising hygiene or food safety.

Whether you produce at industrial scale or in specialised batches, heat recovery can be integrated directly into existing production lines and deliver value from day one.

snack production

Why heat recovery is relevant for snack production

Snack production is characterised by heat-intensive and often continuous processes. Ovens run around the clock, frying lines emit heat, and the industry also demands strict hygiene, cleaning, and process stability – all of which require hot water and controlled temperatures.

The waste heat generated during production represents a valuable energy resource that is typically lost. By capturing and reusing this heat – for example, to preheat process water, feed CIP systems, or drive absorption cooling – snack producers can significantly reduce their energy consumption.

In an industry increasingly focused on sustainability, traceability, and cost-efficiency, heat recovery provides a solution that combines economic logic with responsible operations.

Take the test

Get energised by contributing to a more sustainable future

Let us help you! – We custom solutions for recovering your waste heat, so you can optimize your energy efficiency for the benefit of both the environment and your business.

Can I recover my waste heat?

You can recover up to 95% of waste heat from process air, steam, and flue gases. The surplus energy can be stored or used directly to optimize production processes.

Why heat recovery is important

There are increasing demands for us to take responsibility in the green transition. With the right system, you can reduce your carbon footprint and costs.

Will the investment benefit my business

Our solutions not only enhance your green profile but also improve your financial bottom line. Typically, the investment pays off in 2-3 years.

A great investment

How snack producers utilise waste heat

Spildvarmen i snackproduktion opstår typisk i udsugning fra ovnWaste heat in snack production typically originates from oven exhaust, fryer lines, and drying chambers. With Exodraft’s solutions, this heat can be captured, stored, and reused in other processes – all without compromising food standards or operational performance.

Typical applications include:

- Preheating of process water for mixing, dough preparation, or pre-treatment

- Cleaning systems (CIP), where hot water is essential for hygiene

- Absorption cooling, converting excess heat into cooling in production or packaging areas

- Export to district heating networks, where technically and legally possible

- Strengthening ESG profile and CO₂ documentation

This transforms heat that would otherwise escape through the roof into an active resource in a streamlined, energy-efficient food production setup.

snack food industry

Benefits of Exodraft’s solutions for the snack industry

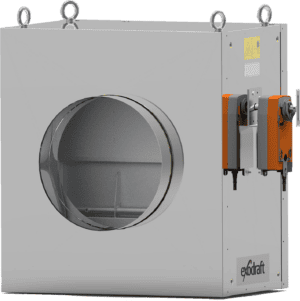

Exodrafts varmegenvindingssystemer er udviklet til at fungere i Exodraft’s heat recovery systems are designed to meet the high demands of food production in terms of operational reliability, hygiene, and temperature stability. Our solutions can be integrated into both new and existing lines – from small niche producers to large, automated snack factories.

Benefits for your business:

- Reuse of heat from ovens, fryers, and extraction systems

- Reduced energy consumption and lower operating costs

- Improved heat balance and comfort in production areas

- Scalable solutions tailored to your needs and capacity

- Sustainable profile with documented CO₂ reductions

Heat recovery is not just about savings – it’s an investment in future-proof and responsible food production.

Contact

Want to know how much you can save?

Heat recovery is an effective way to reduce energy consumption in food production – whether you work with snacks, bread, ready meals, or other food types. At Exodraft, we help companies identify waste heat and turn it into tangible savings.

We offer professional consultancy based on your production setup, processes, and your hygiene and reliability requirements.

Try our Energy Calculator or contact us today for a no-obligation assessment of how much you could save – in terms of energy, operating costs, and carbon footprint.

exodraft