energy optimisation

Scalable, robust and

energy-efficient solutions

Production in the metal industry is often characterised by high temperatures, energy-intensive processes and substantial heat generation – especially during melting, casting and heat treatment. Heat that is not used directly in the process typically ends up as waste.

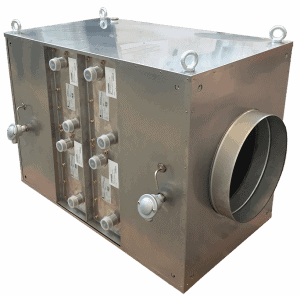

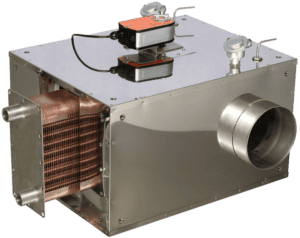

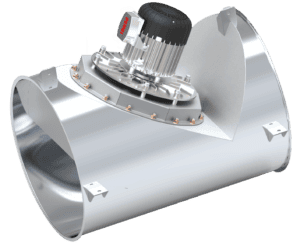

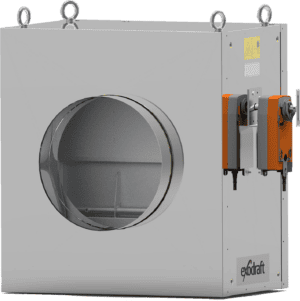

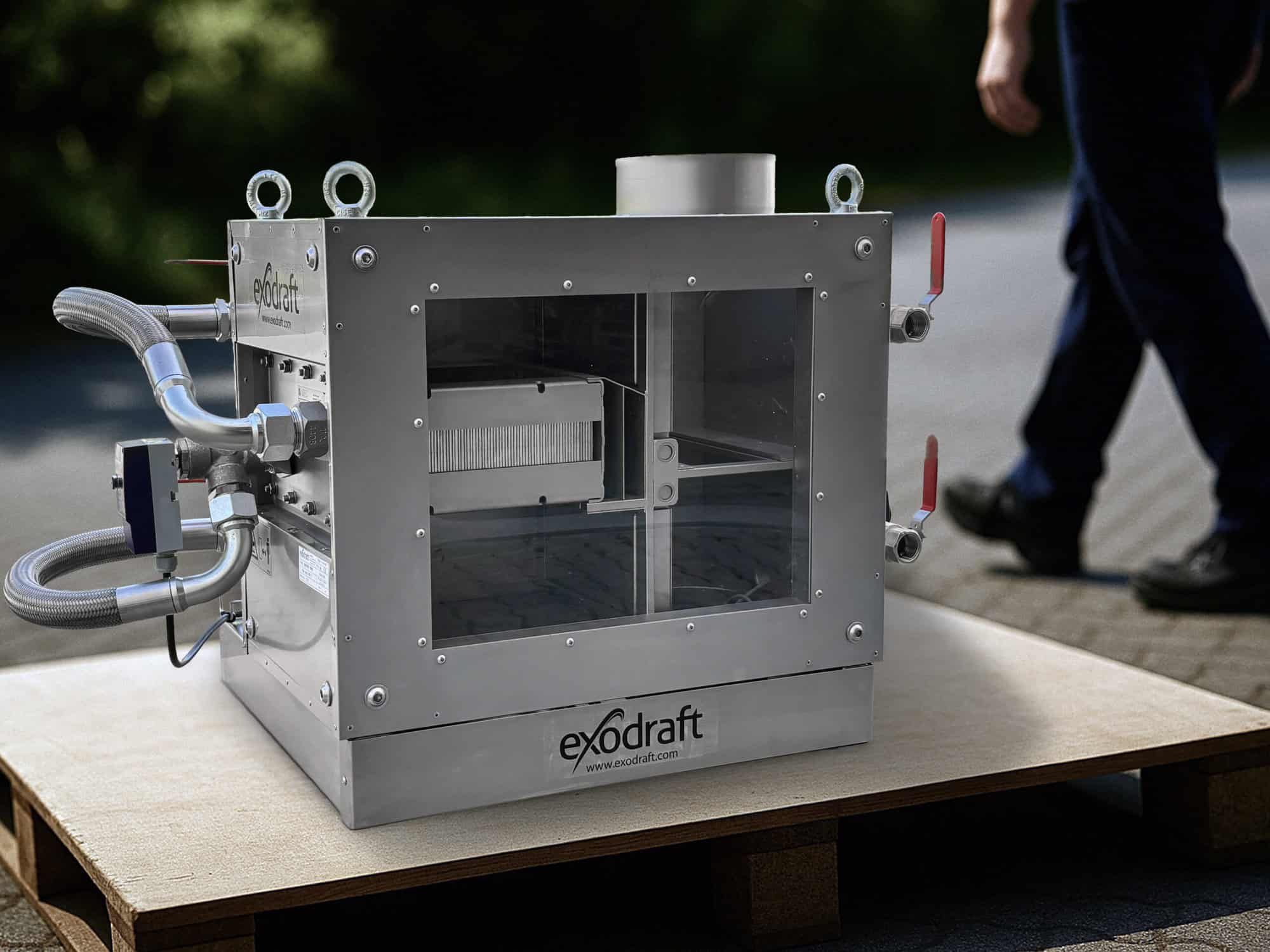

Exodraft’s heat recovery solutions make it possible to capture and reuse this energy. It can be used for heating buildings, preheating process water or even sold via the district heating network – all without negatively affecting production.

Our systems are scalable and robust, making them ideal for everything from small workshops to large industrial metal plants.

metal industry

Why heat recovery is relevant for the metal industry

In the metal industry, heat is not only essential – it is also a significant operational expense. Whether it’s welding, casting, pressing or thermal treatment, vast amounts of surplus heat are generated and often lost unused.

At the same time, many metal companies face rising energy costs and increasing demands for sustainability and emissions reduction – from both customers and authorities. Heat recovery offers a direct solution to both challenges: it recycles energy that has already been paid for and reduces the need for external heating.

This makes heat recovery a smart investment – both economically and strategically.

Take the test

Get energised by contributing to a more sustainable future

Let us help you! – We custom solutions for recovering your waste heat, so you can optimize your energy efficiency for the benefit of both the environment and your business.

Can I recover my waste heat?

You can recover up to 95% of waste heat from process air, steam, and flue gases. The surplus energy can be stored or used directly to optimize production processes.

Why heat recovery is important

There are increasing demands for us to take responsibility in the green transition. With the right system, you can reduce your carbon footprint and costs.

Will the investment benefit my business

Our solutions not only enhance your green profile but also improve your financial bottom line. Typically, the investment pays off in 2-3 years.

a great investment

How metal companies utilise waste heat

I processer som metalsmeltning, udglødning, hærdning, Processes such as metal melting, annealing, hardening, forming, drawing and casting generate large volumes of excess heat.

With Exodraft’s heat recovery solutions, this energy can be captured and redirected back into production.

Typical applications include:

- Heating of production halls and facilities

- Heating of domestic hot water for staff areas and washing

- Preheating process water for washing or chemical treatment

- Absorption cooling – converting heat into cold during warmer periods

- Export to district heating networks, where permitted by infrastructure and regulations

- Strengthening ESG profile and CO₂ documentation

In this way, heat from heavy industrial processes becomes an active energy source – and not just a by-product.

metal industry

Benefits of Exodraft’s solutions for the metal industry

Exodraft’s heat recovery systems are built to withstand the high temperatures and tough environments typical of the metal industry. Whether for small workshops or large industrial plants, we offer robust and flexible solutions that can be integrated into both existing and new production lines.

Benefits for your business:

- Significantly reduced energy consumption and lower operational costs

- Reuse of waste heat from heat-intensive processes like casting and hardening

- Enhanced sustainability profile and reduced carbon footprint

- Integration with district heating systems and cooling technologies

With Exodraft, you get more than an off-the-shelf solution – you get a partner who understands your technical challenges and delivers measurable results.

let us help you

Want to know how much you can save?

The metal industry holds substantial potential for heat recovery – and the savings can have a direct impact on your bottom line. At Exodraft, we offer consultancy, calculations and customised solutions based on your specific production setup and heating needs.

Whether you operate a foundry, a casting plant, or work with metal forming and heat treatment, we can help you make use of the energy you’ve already paid for.

Try our Energy Calculator or contact us today for a no-obligation assessment of how much you can save – in terms of both energy and environmental impact.

exodraft