energy optimisation

Heat recovery can have a significant impact on your operational performance

The meat industry is characterised by high energy demands – from slaughtering and cutting to chilling, packaging and distribution. Heat plays a central role in many of these processes, while at the same time generating significant amounts of waste heat.

With heat recovery from Exodraft, this surplus energy can be captured and redirected back into production. This not only offers financial benefits through reduced energy consumption but also strengthens your sustainability profile.

Our solutions are tailored to the specific requirements of the industry and can be applied across the entire value chain – from slaughterhouses and processing to packaging and cold storage. Whether you operate large-scale facilities or run a specialised plant, heat recovery can make a meaningful difference in your operations.

the meat industry

Why heat recovery is relevant for the meat industry

In meat processing, heat and cold go hand in hand. Large volumes of energy are required to heat water for cleaning and processes – while facilities and products must remain refrigerated. This combination makes energy one of the most significant operational costs.

This is precisely why heat recovery is particularly valuable in this industry: surplus heat can be reused not only for process water and cleaning but also for absorption cooling – converting excess heat into active refrigeration. This reduces electricity use and helps balance the facility’s total energy needs.

Processes such as scalding, cleaning, pasteurisation and thermal treatment generate substantial excess heat, which is lost without recovery. By capturing and reusing this heat, businesses in the meat industry can achieve major savings and significantly reduce their CO₂ footprint.

Heat recovery also enables better control of energy use, supporting robust ESG reporting. In a sector with strict hygiene and efficiency requirements, it’s a strategic solution that benefits both economy and the environment.

Take the test

Get energised by contributing to a more sustainable future

Let us help you! – We custom solutions for recovering your waste heat, so you can optimize your energy efficiency for the benefit of both the environment and your business.

Can I recover my waste heat?

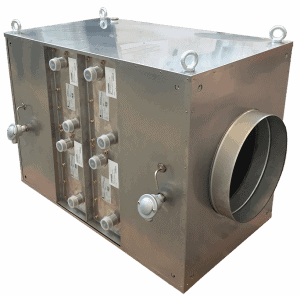

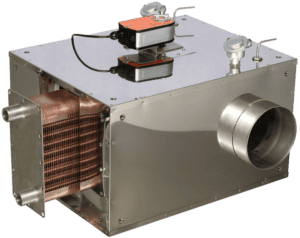

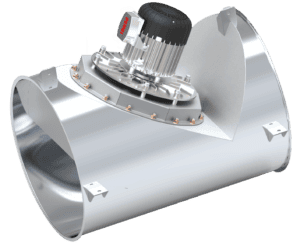

You can recover up to 95% of waste heat from process air, steam, and flue gases. The surplus energy can be stored or used directly to optimize production processes.

Why heat recovery is important

There are increasing demands for us to take responsibility in the green transition. With the right system, you can reduce your carbon footprint and costs.

Will the investment benefit my business

Our solutions not only enhance your green profile but also improve your financial bottom line. Typically, the investment pays off in 2-3 years.

a great investment

How the meat industry utilises waste heat

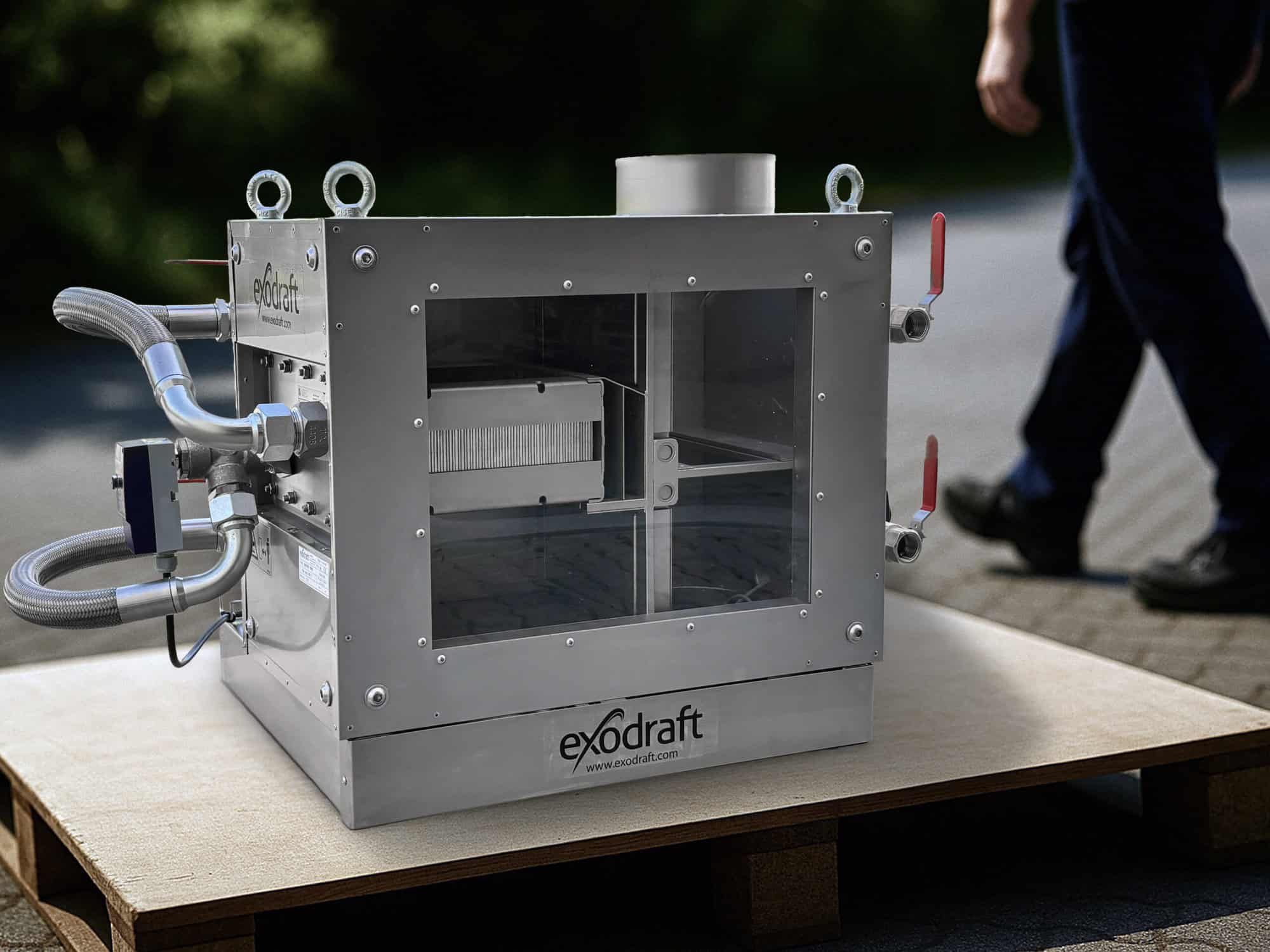

Spildvarme fra kødproduktion rummer et stort energipotentiale – særligt fordi mange af processerne foregår ved høje Waste heat from meat production holds great potential – particularly because many processes operate at high temperatures and run continuously. With Exodraft’s solutions, this heat can be recovered and targeted towards other areas of the production.

Typical applications include:

- Heating domestic water, e.g. for cleaning and CIP systems

- Cleaning operations

- Space heating of buildings

- Absorption cooling – converting surplus heat into refrigeration

- Export to district heating networks, where permitted

- Strengthened ESG profile and CO₂ documentation

By keeping energy in circulation, the need for external energy supply is reduced – creating a more stable and sustainable energy system.

the meat industry

Benefts of Exodraft’s solutions for the meat industry

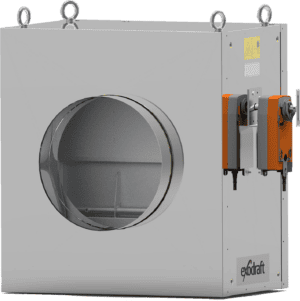

Exodrafts varmegenvindingssystemer er udviklet til at matche Exodraft’s heat recovery systems are designed to meet the technical and hygiene standards required in meat processing. Our solutions are scalable and adaptable across all stages of the value chain – from slaughtering and processing to packaging and chilled storage.

Benefits for your business:

- Proven energy savings and short payback time

- Lower CO₂ emissions and enhanced sustainability profile

- Compatibility with existing process equipment and production flow

- Reliable and low-maintenance installations

Whether you operate large-scale or niche production, our focus is to deliver a solution that produces measurable results and supports your green transition.

let us help you

Want to know how much you can save?

With Exodraft’s heat recovery solutions, the meat industry gains an effective method to reduce energy consumption and make use of waste heat from production. We offer tailored consultancy based on your processes and operational needs – whether in slaughtering, processing, or distribution.

Try our Energy Calculator or contact us today for a no-obligation assessment of how much you could save – both economically and environmentally.

exodraft