energy optimization

Energy-efficient operation and reduced heat emission

Glass manufacturing is one of the most heat-intensive industries. Melting furnaces, forming lines, tempering zones and cooling tunnels operate at extremely high temperatures – often continuously – and release substantial amounts of waste heat. The unused heat typically escapes via exhaust systems or flue gas.

With Exodraft’s heat recovery solutions, this energy can be captured and returned to the production process – for example, to heat process water, buildings, or domestic water. This enables more energy-efficient operations and reduces thermal emissions.

Whether you produce window glass, packaging glass, technical glass, or insulation materials, heat recovery can be integrated into your setup – without compromising product quality.

glass manufacturing

Why heat recovery is relevant for glass manufacturing

In glass production, raw materials are melted at temperatures exceeding 1,400°C, after which the glass is shaped, tempered and cooled under controlled conditions. These processes generate vast amounts of heat – especially from melting furnaces, hot forming tools, and cooling ducts – much of which is typically lost through flue gas or extraction.

At the same time, glassworks require significant energy for heating elsewhere in the production process – such as for process water, cleaning systems, and comfort heating in large production halls. Heat recovery offers a clear opportunity to balance thermal surpluses and heating demands internally within the business.

For glass manufacturers aiming to reduce their energy consumption and carbon footprint without compromising operational reliability or product quality, heat recovery presents both a practical and strategic solution.

Take the test

Get energised by contributing to a more sustainable future

Let us help you! – We custom solutions for recovering your waste heat, so you can optimize your energy efficiency for the benefit of both the environment and your business.

Can I recover my waste heat?

You can recover up to 95% of waste heat from process air, steam, and flue gases. The surplus energy can be stored or used directly to optimize production processes.

Why heat recovery is important

There are increasing demands for us to take responsibility in the green transition. With the right system, you can reduce your carbon footprint and costs.

Will the investment benefit my business

Our solutions not only enhance your green profile but also improve your financial bottom line. Typically, the investment pays off in 2-3 years.

a great investment

How glass manufacturers utilise waste heat

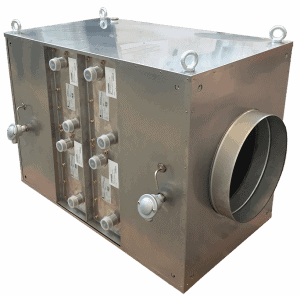

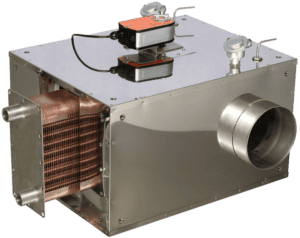

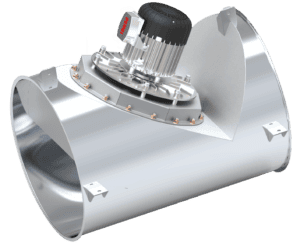

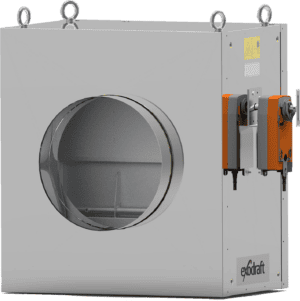

Glass manufacturing generates waste heat at several stages: from melting furnaces and forming zones to cooling tunnels and post-processing areas. With Exodraft’s heat recovery systems, this energy can be efficiently captured – without disrupting sensitive parts of the process.

Typical applications include:

- Heating of production halls and technical rooms

- Heating of domestic water for cleaning, washing and sanitation

- Preheating of process water, e.g. for raw material preparation

- Absorption cooling – converting heat into cold for control rooms, warehouses and offices

- Export to district heating networks, where local infrastructure allows

- Strengthened ESG profile and CO₂ documentation

With proper system design, we ensure that the recovered energy is used where it creates the most value – without affecting glass quality or production stability.

the glass industry

Benefits of Exodraft’s solutions for the glass industry

Exodrafts systemer er bygget til at håndtere de ekstreme tExodraft’s systems are built to withstand the extreme temperatures and continuous loads typical in glass production. We deliver solutions that perform reliably in energy-intensive melting departments as well as in more sensitive forming and cooling zones – without compromising process stability.

Benefits for your business:

- Efficient utilisation of heat from furnaces, tempering zones, and cooling tunnels

- Reduced energy consumption and lower heat emissions

- Integration into both existing and new production lines

- Scalable solutions for both large and small glass manufacturers

- Documented CO₂ reduction and enhanced ESG profile

Whether you produce float glass, packaging glass or speciality glass, heat recovery can give you a technical and financial advantage.

let us help you

Want to know how much you can save?

The glass industry holds significant untapped energy potential – particularly in melting and cooling processes. With Exodraft’s heat recovery solutions, you gain the opportunity to convert waste heat into tangible value while improving your company’s sustainability profile.

We offer tailored consultancy and potential calculations based on your specific production setup and plant type.

Try our Energy Calculator or contact us today for a no-obligation assessment of how much you could save – in terms of both energy and carbon footprint.

exodraft