energy optimisation

Stabile and efficient operation

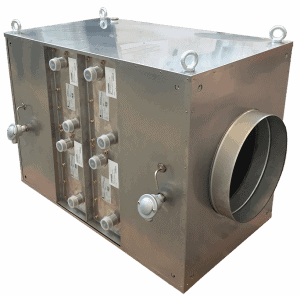

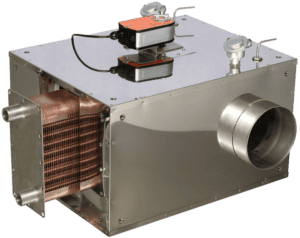

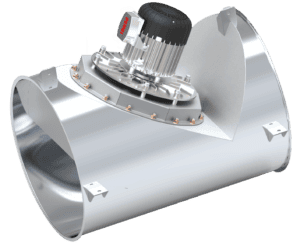

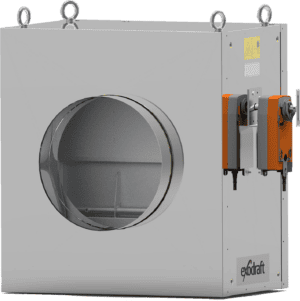

With Exodraft’s heat recovery systems, excess heat can be captured and reused for new purposes – such as heating buildings, domestic hot water, or process water. This reduces energy consumption and ensures more stable and efficient operations.

Whether you’re working with electroplating lines, powder coating booths, or combined surface treatment facilities, heat recovery can be implemented without interfering with sensitive process parameters.

surface treatment

Why heat recovery is relevant for the surface treatment industry

Surface treatment facilities often operate 24/7 with constant heat generation from electrolyte tanks, rinsing stages, pre-treatment zones, and particularly drying and curing ovens. These systems require high and stable temperatures – and emit large amounts of waste heat via exhaust and process air.

At the same time, energy consumption in galvanic and powder-based processes ranks among the highest in industrial production – especially in operations with multiple shifts and fast throughput. Heat recovery presents an ideal opportunity to harness energy from processes such as cathodic dip coating or powder curing – and return it to production or repurpose it elsewhere.

This leads to reduced heat emissions, lower energy losses, and strengthens the company’s ability to meet efficiency targets and climate goals.

Take the test

Get energised by contributing to a more sustainable future

Let us help you! – We custom solutions for recovering your waste heat, so you can optimize your energy efficiency for the benefit of both the environment and your business.

Can I recover my waste heat?

You can recover up to 95% of waste heat from process air, steam, and flue gases. The surplus energy can be stored or used directly to optimize production processes.

Why heat recovery is important

There are increasing demands for us to take responsibility in the green transition. With the right system, you can reduce your carbon footprint and costs.

Will the investment benefit my business

Our solutions not only enhance your green profile but also improve your financial bottom line. Typically, the investment pays off in 2-3 years.

a great investment

How surface treatment companies utilise waste heat

In galvanic and powder-based surface treatment, waste heat primarily arises from drying ovens, preheating zones, and extraction systems. Exodraft’s heat recovery solutions make it possible to capture this heat and reuse it directly in operations.

Typical applications include:

- Preheating of process water for tanks and chemical baths

- Heating of production halls and ventilation air

- Heating of domestic water for rinsing and cleaning systems

- Absorption cooling, where heat is converted into cold in coating environments

- Export to district heating networks, where infrastructure allows

- Strengthening ESG profile and CO₂ documentation

Each solution is tailored to the specific installation – whether a fully automated galvanic line or a powder coating booth – and implemented with minimal interference to existing systems.

galvanic and powder coating

Benefits of Exodraft’s solutions for electroplating and powder coating

Exodraft’s systems are designed to handle complex industrial environments, where temperature-sensitive processes and continuous operations demand stability and precision. We deliver customised heat recovery solutions that integrate seamlessly into surface treatment facilities without disturbing chemical or thermal processes.

Benefits for your business:

- Reuse of waste heat from drying and curing processes

- Reduced energy consumption and heat emissions

- Lower operating costs and fast return on investment

- Improved energy balance within production

- Strengthened ESG profile and CO₂ documentation

Whether you work with zinc coating, anodising, or powder coating, Exodraft delivers a solution that supports both efficient operations and the green transition.

Let us help you with the right solution

Want to know how much you can save?

Heat recovery is a clear opportunity for companies involved in galvanic and powder-based surface treatment that aim to reduce energy consumption and enhance their sustainability profile.

At Exodraft, we help identify your waste heat potential and convert it into tangible savings and energy improvements.

Try our Energy Calculator or contact us today for a no-obligation assessment of what you could save – technically, financially, and environmentally.

exodraft