Your optimization partner

Scalable solutions for your needs

By capturing excess heat directly from process or extraction systems, it can be reused for heating domestic water, process water, buildings, or even supplied to district heating networks. This reduces energy consumption and supports a more sustainable and efficient production – whether you run a microbrewery or a large-scale facility.

Our solutions are scalable and can be adapted to both new and existing installations, ensuring that energy stays within the business – where it creates value.

brewery- and destillery production

Why heat recovery is relevant for brewery and destillery production

Beverage production is one of the most heat-intensive industries. Processes such as mashing, boiling, distillation, and CIP (clean-in-place) cleaning require vast amounts of energy – and produce equally large amounts of waste heat.

At the same time, both food safety standards and consumer expectations demand increasing levels of sustainability and responsible resource use. Heat recovery meets these demands by reducing energy consumption, lowering CO₂ emissions, and providing better control over the production’s overall energy balance.

For both small and large breweries and distilleries, heat recovery is not only a green initiative – it’s also a way to achieve operational savings and strengthen competitiveness.

Take the test

Get energised by contributing to a more sustainable future

Let us help you! – We custom solutions for recovering your waste heat, so you can optimize your energy efficiency for the benefit of both the environment and your business.

Can I recover my waste heat?

You can recover up to 95% of waste heat from process air, steam, and flue gases. The surplus energy can be stored or used directly to optimize production processes.

Why heat recovery is important

There are increasing demands for us to take responsibility in the green transition. With the right system, you can reduce your carbon footprint and costs.

Will the investment benefit my business

Our solutions not only enhance your green profile but also improve your financial bottom line. Typically, the investment pays off in 2-3 years.

A great investment

How beverage producers utilise waste heat

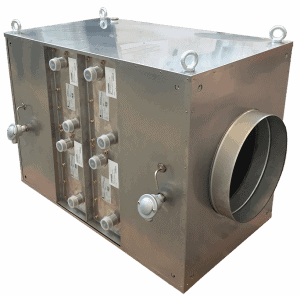

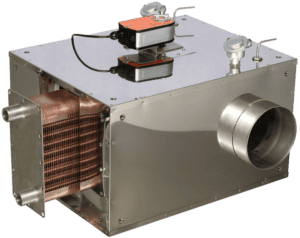

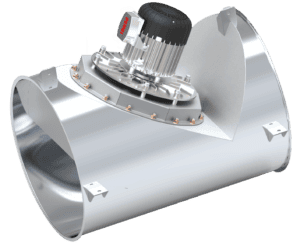

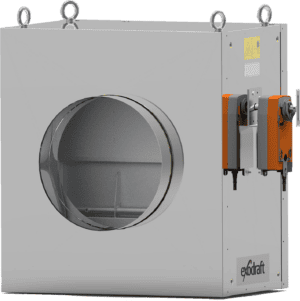

Heat recovery in breweries and distilleries is about using energy where it delivers the most benefit – and it can be done far more efficiently than many expect. With Exodraft’s solutions, waste heat from production, such as from gas boilers, can be reused across various functions within the facility.

Typical applications include:

- Heating domestic hot water, e.g. for bottling, cleaning, or staff facilities

- Preheating process water, improving energy efficiency in the brewing process

- Heating buildings, including offices, warehouses, and production areas

- Absorption cooling, where heat is used to generate cold during the summer

- Exporting to district heating networks, turning surplus energy into a new revenue stream

- Strengthening ESG profile and CO₂ documentation

These applications ensure that energy is kept in circulation – and directly contributes to the company’s financial and sustainability goals.

breweries and destilleries

Benefits of Exodraft’s solutions for breweries and distilleries

Exodraft’s heat recovery systems are designed to meet the specific technical and hygiene-related requirements of the beverage industry. Our solutions are flexible, reliable, and easy to integrate into both new and existing production facilities.

Benefits for your production:

- Significant energy savings and reduced operational costs

- Better utilisation of energy already paid for

- Increased sustainability and lower CO₂ emissions

- Scalable solutions suitable for both microbreweries and large-scale operations

- Minimal disruption to existing operations during implementation

With Exodraft, you don’t just get a technical solution – you gain an experienced partner who understands your industry and ensures you get the most out of your energy investment.

Exodraft

Want to know how much you can save?

Do you want to reduce energy consumption in your brewery and make your business more sustainable? With Exodraft’s heat recovery solutions, you’ll get proven savings and full control over your energy usage.

We help you analyse your heat consumption and identify the best opportunities for reuse – whether you operate a distillery, microbrewery or large-scale production facility.

Try our Energy Calculator or contact us today for a no-obligation assessment of your savings potential.

exodraft