bakeries

Why heat recovery is relevant for bakeries

Bakeries have a high and consistent energy demand – especially in the ovens, where large volumes of air are heated daily. Whether it’s tunnel ovens, deck ovens or rack ovens, substantial amounts of heat are released during the baking process and typically vented directly through the chimney.

At the same time, many bakeries are facing rising energy costs, stricter environmental regulations, and increased pressure to document sustainable initiatives. Here, heat recovery provides a tangible solution: by capturing and reusing waste heat, bakeries can significantly reduce energy consumption, improve their CO₂ balance, and meet the growing demands for green transition from both regulators and customers.

The recovered heat can be used for preheating process water, heating buildings, cleaning water, or even for absorption cooling during warm periods. The right solution transforms waste heat from an overlooked by-product into an active part of your energy optimisation strategy.

Take the test

Get energised by contributing to a more sustainable future

Let us help you! – We custom solutions for recovering your waste heat, so you can optimize your energy efficiency for the benefit of both the environment and your business.

Can I recovery my waste heat?

You can recover up to 95% of waste heat from process air, steam, and flue gases. The surplus energy can be stored or used directly to optimize production processes.

Why is heat recovery important

There are increasing demands for us to take responsibility in the green transition. With the right system, you can reduce your carbon footprint and costs.

Will the investment benefit my business

Our solutions not only enhance your green profile but also improve your financial bottom line. Typically, the investment pays off in 2-3 years.

a great investment

How bakeries effectively utilise waste heat

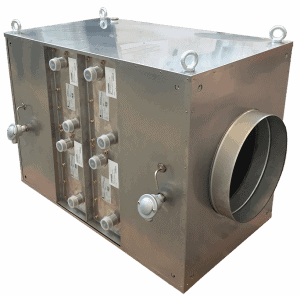

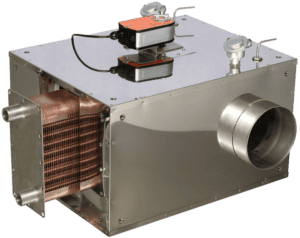

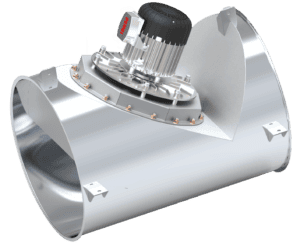

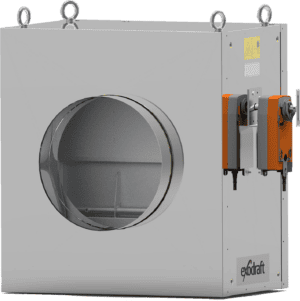

In the bakery sector, the potential for heat recovery is considerable. With Exodraft’s solutions, waste heat from ovens can be captured and reused as hot water in other parts of the production process – with great effect.

Typical applications in bakeries include:

- Heating of cleaning water

- Preheating of process water for steam generation

- Heating of office and staff facilities

- Absorption cooling before packaging

- Supplying energy to production processes

- Export to district heating networks, where possible

- Strengthening ESG profile and CO₂ documentation

bakery industry

Benefits of Exodraft’s solutions for the bakery industry

When you choose Exodraft as your partner, you get more than just components. You get a solution tailored to the specific needs and challenges your bakery faces – and a partner with proven experience from similar projects.

Benefits for your bakery:

- Reduced energy consumption and lower operating costs

- Measurable CO₂ reduction and improved sustainability profile

- Solutions adapted to both new and existing facilities

- User-friendly control and monitoring of energy data

- Professional consultation and technical support throughout

Whether you operate a single bakery or multiple locations, Exodraft’s systems and solutions can be scaled and customised to deliver maximum impact and fast return on investment.

EXODRAFT

Want to know how much you can save?

At Exodraft, we help bakeries turn waste heat into real savings. Whether you’re looking to reduce energy costs, optimise production, or enhance your company’s green profile, our experts are ready to assess your potential.

We offer consultancy, energy calculations and bespoke solutions based on your processes and needs – and we stay with you throughout the project, from the initial analysis to commissioning and ongoing service.

exodraft